The Birth of an Insulator

by Mark Lauckner

Reprinted from "Crown Jewels of the Wire", July 2000, page 33

The way that insulators are conceived and born often result in unique

characteristics that us collectors like, (not like us collectors). From my

experience making approximately 1000 old threadless-shaped commemorative

insulator paperweights, I have witnessed all of the little problems that

produce" birthmarks" and defects in old pressed glass. As my glass

pressing techniques are as authentic as possible to the old pioneer

technologies, this has been quite an exciting learning curve. What follows is a

combination of my personal observations and some research into pioneer glass

manufacturing.

What causes leaners?

Leaners or "slumpers" are the result of one of two events. Either

the insulator was released from the mold too soon and shifted in shape a bit

before rigidizing, or the temperature during the annealing process was too high

and the glass sunk a little under its own weight.

A leaning two-tone

CD 121 Pleated Skirt

What causes underpours?

What we call "underpours" are hardly ever caused by an insufficient

volume of glass in the mold. They are usually caused because the glass cools

before it can be squeezed into the small areas of the mold. This is why underpours occur on the base and inner skirt region. This is the area

where there is the most amount of mold around the smallest amount of hot glass.

In old insulators, the plunger depth or skirt length compensated for the different volumes of glass portioned for each pressing. This results in a deeper

pinhole or shorter insulator if there is a smaller portion of glass in the mold,

so a true "underpour" is a very rare occurrence.

Underpoured base on a

CD 161 California.

What causes snow in insulator glass?

Snow is small particles of eroding furnace brick which has broken up and

flowed out in the glass tank. The glass tank bricks were usually a high alumina

firebrick, so the main component in the snow would be clay particles. (Modern

glass tanks are made from fused zirconia brick.) If the particles are larger

than a sesame seed, they can cause fractures because the glass contracts around them during cooling. This usually only

affects the area close to a surface. "Pot stones" are simply larger

pieces of eroding furnace brick becoming suspended in the glass. Pot stones the

size of a dried pea are usually significant enough to always cause a fracture

during cooling.

This CD 145 H.G.CO. beehive

looks like a snowy blizzard.

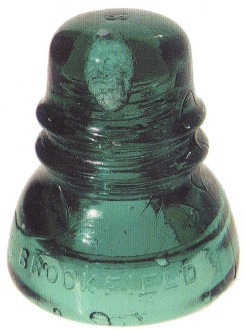

A huge pot stone in the dome

of a CD 152 Brookfield.

How do objects get inside insulator glass?

Metal objects like nails, coins, wire, and bottle caps have been found in

insulators. Metals with a higher melting temperature than the glass will remain

intact for a while, but would eventually be dissolved by the hot caustic nature

of the glass fluxes. These objects are everyday types of junk, and were probably

introduced into the glass tank through shoveling cullet (broken bottles, one

with cap still on neck!), floor sweepings, etc..

Skirt length bent nail in a

CD 102 N.E.G.M. Co.

A 1920 Lincoln penny in the

dome of a Hemingray-42.

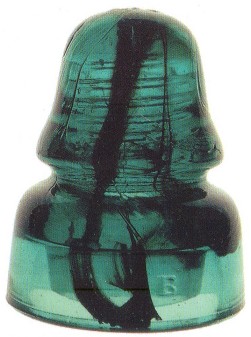

What causes creases and lines on insulators?

These are sometimes referred to as "straw lines" or "cold

mold" and are lines in the glass surface where cooling has occurred during

the pouring and the pouring stream did not completely melt back together during

the squeezing. The liquid glass folds over itself as it fills the mold and the

creases are hardened in position when they touch the-sides of the mold. The

glass does melt back together on the inside, but because the outer glass is

contacting the (cooler) mold parts, the glass can't retain the heat needed to

completely fuse back together again on the surface.

Straw lines on this cornflower

blue CD 106 Duquesne show up

on the skirt below

the embossing.

"Cold mold" is something entirely different. If the mold is not at

least 1000° F., then the glass stream entering the mold will cool instantly as

it flows over itself. This causes a concentric rippling effect, much like

throwing a stone into a pond. They are occasionally seen on the domes of

insulators, but are not caused the same way as creases and folds in the glass.

The parallel thin lines which are often seen over the dome and down one side

of an insulator are from a long thin "stringer" which enters the mold

before the rest of the pour. This only occurs when multiple insulator molds were

being filled from the same ladle, because the glass never actually breaks clean

at the end of a previous pouring. It just hardens with a little thread on the

end, which becomes the first part to enter the next mold as the pouring begins again. This is

evident on lots of H.G. Co. signals and on lots of Brookfield products, too. The

thin parallel lines can be followed until they branch away from each other. This

is the point where the hardened stringer on the bottom of the pour is attached

to the hotter contents of the ladle.

Concentric rippling of the dome

glass on the CD 145 H. G. Co.

Petticoat

formed when the

molten glass was poured into

a mold that is cold.

Parallel lines of a stringer on front

of an H.G.Co. signal's dome.

Later, with automatic portioning machines,

the glass stream was cut or sheared off for each mold filling. This often left a

shear mark about 3/4" long somewhere on the bottom of the mold (on the

dome). Lots of the later era glass insulators have this marking on one side of the dome, like Dominions, Whitall Tatums, Armstrong, etc.

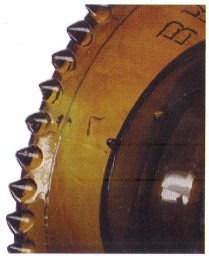

What are those little drip points on some inner skirts?

These are air vents. Little holes are drilled into mold parts which have the

potential to trap air during the pressing. The inner skirt is often the only

place on the pressing where there is a surface with no moving mold part. The

small spaces between moving mold parts allow trapped air to escape during the

squeezing of the glass in the mold. Several styles of Brookfield insulators were

pressed in this type of mold, and no mold line can be found on the inner edge of

these inner skirts.

The inner skirt of a Brookfield signal

showing the small air vent drip point.

Most of these occur in each of the four

quadrants of the inner skirt's

circumference.

What causes amber streaks?

Amber streaks are caused by iron oxide (rust) or ferrous containing metals in

the glass. Just one little fleck of rust or scrap iron causes a nice amber

streak when poured. If rusty steel or iron ladles were used to pour insulators,

rust flecks would be left in the glass tank after each time the ladle was dipped

in. These flecks would melt and make little regions of dark green glass waiting

for the ladle to come back and scoop them up for the next pour. Iron oxide is

one of the oxides used for coloring glass green. When we refer to amber

streaking in glass, it's usually green that we see.

What causes milk streaks?

"Milk" or non-transparent streaks are the result of accidental

contamination by a chemical oxide which acts as an opacifier in the glass, or

the deliberate addition of these chemicals in the previous furnace batch to

produce opalescent or opaque glass. (See two-tones.) Small milk streaks in an

insulator would certainly suggest undesired contamination in the glass tank,

while the fully swirled milky insulators (like the Hemingray-9 and 12's) would

suggest that transparent glass was loaded on top of a previous run of opaque or "milk glass", and that some mixing

action in the glass tank had partially blended the two together.

A radical amber streak in a

CD 162.5 PRR (dome embossed)

made by Brookfield.

Jade milk and milk-streaked Hemingray - 9's (CD 106).

The chemicals

used as opacifiers in glass were usually calcium fluoride (fluorspar), fluorine,

calcium phosphate, or sodium phosphate. Nowadays, to obtain the right balance of

phosphorous oxides in the glass, tri-sodium phosphate (TSP) is the main

opacifier used. The fluorides and fluorines are used to produce the opalescent

glasses which have an orange-ish tint when held up to a light source (will pass

light like the opalescent Hemingray and Fry insulators). A little TSP in aqua

glass would result in the "jade milk" Hemingray products.

What causes two-tone colors in insulators?

Two-tone insulators are the result of one color of glass being loaded into an

almost empty furnace on top of another color. When the area lower in the tank is

scooped out to pour insulators, the region where the 2 colors meet can be the

gathering area for the ladle. The pour then enables both colors to enter the

mold at the same time.

A Hemingray CD 162 signal

with a two-tone mixture of

aqua and clear glass.

What causes vapor bubbles in glass?

When little flecks of metals (with lower melting temperatures than glass) get

into hot glass, they melt and emit a vapor, causing a little bubble around the

fleck. This burns off within a few minutes, and the bubbles rises to the surface

of the glass pot and pop. Various metals melt within the temperature range of

liquid glass (2400° F.).

When flecks of metals get imbedded in hot glass, the vapor pressure of the

evaporating metal causes a bubble. When the glass cools, the metal vapor

condensates on the inside of the bubble cavity. The metals condensate back to

their original colors, for example, aluminum looks like shiny silver and copper

looks dull reddish-brown.

What causes black bubbles in glass?

Bubbles with black sides are carbon or graphite. They would be from sawdust

or small wood chips getting trapped in the hot glass. As they burned, a gas was

released causing the bubble. When the glass cooled, the vapor condensated and

deposited graphite (carbon) on the inside of the bubble.

Huge black bubble in the

skirt of a CD 126.1 Brookfield.

What causes bubbles in glass?

Tiny "seed" bubbles are the result of incomplete glass ingredient

melting. The alkali which dissolves the silica in the melting action

creates small gas bubbles. These bubbles take a long time to rise to the surface and pop, and usually become suspended in the

molten glass. They can be squeezed out by reducing the temperature in the

furnace and then raising it again. This is referred to as "pinching"

the glass, but wasn't done very often with old insulator glass because optical

clarity wasn't required.

Seed bubbles throughout a H.G.Co.

Petticoat beehive (CD 145).

For any bubble bigger than a seed bubble to be trapped

in glass, the air must have been trapped very close to the time the glass was

being poured and cooled. Most bubbles are trapped during pouring and are pressed

into place as the glass cools in the mold. In the furnace, large bubbles would

rise and pop on the surface, so no large bubbles would exist in the glass

supply.

This bubble is about the size

of half of the skirt. Not sure

how the piece

screwed on a pin,

for the inside of the airspace is broken.

What makes color in glass insulators?

Metals, mostly metal oxides, produce color in glass.

Unintentional coloring:

This is the result of melting raw minerals contaminated with trace metal ores.

It can also be the result of contamination from the melting equipment. A good

example of this is the pioneer blackglass. This glass is actually very dark

green and is the result of heavy iron contamination. Melting glass in an iron

furnace pot produces this oversaturated "blackglass". The more common

accidental coloring is the result of excavating silica sand deposits

contaminated with iron and copper oxide impurities. Mined silica sand for glass

making needs to be extensively washed and cleaned in order to produce good

quality glass. This simply wasn't required for insulator production. Varying

degrees of iron and copper oxides produce the vast array of aquas and greens we

see in insulators.

Intentional coloring: Perhaps the most common intentional coloring of pioneer

insulators would be cobalt blue and amber. These insulators are usually from

glass companies using bottle glass to press insulators. Cobalt oxide is added in

very small amounts to glass ingredients to produce the cobalt blue color. It

produces cornflower blue in very, very tiny amounts. Amber is produced with

sulphur and iron oxide. Amber and cobalt bottles were intentionally made for

medicines and liquids which required some UV protection.

Some blue and amber insulators were marketed in the early 1900's as line

markers and would have been intentionally colored. These H.G.Co. and Hemingray

insulators wound up being various shades of yellow, amber, red amber, brown

amber and also electric blue, peacock blue, and various cobalt blues. Yellow can

be produced by adding sulphur to the glass batch. Very small amounts still

produce the yellow color. It's an inexpensive additive and is widely used.

Larger amounts mixed with small amounts of iron oxide produce the golden, red;

and deep root beer ambers, while the electric blue is achieved with copper

carbonate. Turquoise blue is the result of mixing small amounts of cobalt oxide

with the copper carbonate. Hemingray blue requires slightly more cobalt in the

copper carbonate. Iron oxide (better known as rust to all of us who own older

vehicles) by itself produces emerald-olive green. Copper oxide produces, a pea

soup green which is slightly opaque (jade milk glass).

(Photographs provided by Dwayne Anthony. Gary Kline and John McDougald.)

|